Are you curious to know what is HDF wood? You have come to the right place as I am going to tell you everything about HDF wood in a very simple explanation. Without further discussion let’s begin to know what is HDF wood?

When it comes to the world of wood-based materials, HDF (High-Density Fiberboard) is a versatile and widely used option. This engineered wood product offers a range of benefits that have made it a popular choice in various industries. In this blog, we will explore what HDF wood is, how it is manufactured, its applications, and the advantages it offers in construction and interior design.

What Is HDF Wood?

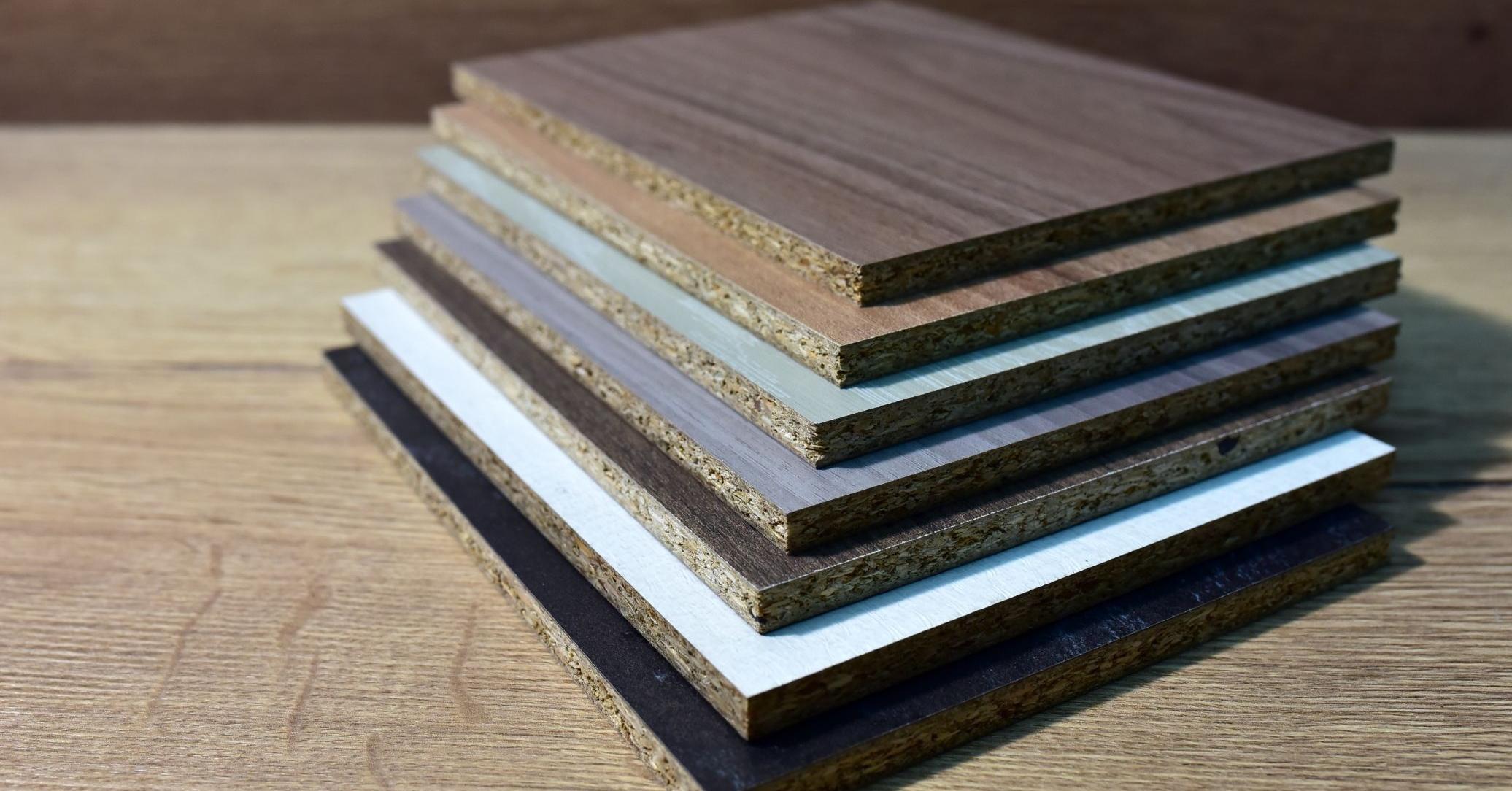

High-Density Fiberboard (HDF) is an engineered wood product that consists of wood fibers, wax, and resin compressed at high pressures and temperatures to create a dense and uniform board. Unlike traditional plywood or particleboard, HDF is made from wood fibers that are broken down into smaller elements, which are then combined and bonded together to form a sturdy and smooth surface.

Manufacturing Process

The manufacturing process of HDF wood involves several key steps:

- Wood Fiber Production: Wood fibers are extracted from various sources, including wood chips, sawdust, and wood shavings.

- Fiber Treatment: The wood fibers are treated with adhesives, such as wax and resin, which help bond them together during the pressing process.

- Formation: The treated wood fibers are then combined and spread out on a forming belt or mat. This forms a dense layer of fibers.

- Pressing: The mat of wood fibers is placed in a hydraulic press, where it is subjected to high pressure and temperature. This compresses the fibers and activates the adhesives, creating a solid, smooth board.

- Cutting and Shaping: The resulting HDF sheets can be cut into various sizes and shapes, depending on the intended application.

Applications Of HDF Wood

HDF wood finds application in a wide range of industries and uses due to its versatility, durability, and smooth surface. Some common applications include:

- Furniture: HDF is often used for manufacturing furniture, including tables, cabinets, and shelving units. Its smooth surface allows for easy finishing with paint, laminate, or veneer.

- Flooring: HDF is a popular material for laminate flooring. Its density and strength make it ideal for withstanding the wear and tear of daily foot traffic.

- Cabinetry: HDF is used for constructing kitchen cabinets and bathroom vanities. Its stability and ability to hold paint and finishes well make it a reliable choice for these applications.

- Doors: HDF can be used to create interior doors due to its smooth surface, which can be painted or veneered to match interior decor.

- Paneling: HDF panels are employed for decorative wall paneling, providing a sleek and polished look to interior spaces.

Get Information About Advantages On Mainadvantages.

Advantages Of HDF Wood

- Smooth Surface: HDF has a consistent, smooth surface that is perfect for painting, veneering, or applying laminate. It results in an attractive and polished appearance.

- Durability: HDF is known for its strength and resistance to warping or bending, making it suitable for high-traffic areas.

- Cost-Effective: It is a cost-effective alternative to solid wood or plywood, making it an attractive choice for budget-conscious projects.

- Versatility: HDF can be easily cut, shaped, and finished to suit various applications and design preferences.

- Environmentally Friendly: Many manufacturers use sustainable wood sources and eco-friendly adhesives in the production of HDF, contributing to its eco-conscious appeal.

Conclusion

HDF wood, with its smooth surface, durability, and versatility, is a valuable engineered wood product used in a wide range of applications. Whether in furniture, flooring, cabinetry, or decorative paneling, HDF offers an affordable and reliable solution. Its environmental sustainability and adaptability have solidified its place in the world of construction and interior design, making it a go-to choice for various projects.

FAQ

What Are The Disadvantages Of HDF?

MDF/HDF does not have good holding strength when compared to real wood. If being used for furniture items that need to be frequently dismantled/reassembled, it may not be your best choice. MDF/HDF cannot come into contact with water, as it will make the fibers swell and damage is very hard to repair.

Is HDF Better Than Wood?

HDF Board is made from beautiful particles meaning that it does not have noticeable grain. This results in a better and smooth finish, especially when the board is painted. If you plan to get the cabinet doors painted, we would highly recommend HDF over solid wood.

What Is Better Mdf Or HDF?

HDF is stronger and more durable than MDF due to its higher density and smaller wood fibres. HDF is less prone to chipping, cracking, and warping than MDF, and is better suited for applications where strength and durability are essential.

What Is The Lifespan Of HDF Wood?

Though HDF is a wood-based material, it is not as durable as natural wood. Hardboard is, however, superior to MDF and particle board regarding strength, durability, and water resistance. These boards have a lifespan of 30 to 40 years.

I Have Covered All The Following Queries And Topics In The Above Article

What Is Engineered Wood Flooring, HDF Or Plywood

What Is Wood HDF

What Is The Meaning Of HDF Wood

What Is The Difference Between Mdf And HDF Wood

HDF Wood Disadvantages

Is HDF Waterproof

HDF Full Form

HDF Vs Plywood

HDF Vs Mdf Cabinets

HDF Wood Price

HDF Meaning

Mdf Wood

What Is HDF Wood

Is HDF better than MDF